The rising market power of sustainable fashion was on display, appropriately enough, inside a former electrical plant for the January 2018 edition of the Ethical Fashion Show Berlin.

Now held under one roof at Kraftwerk Berlin, the three-day event combined conferences about fashion sustainability and technology with runway shows which featured garments made of recycled/upcycled materials and a showcase for products made with eco-friendly practices. According to the event's organizers, 170 labels from 26 countries presented collections for the A/W 2018/19 season.

Contributor Natalie Nazemi and photographer Kimberly Lauren Bryant attended the Ethical Fashion Show Berlin for THE KINDCRAFT. Here are Natalie's notes and highlights from the show, as well as selected videos from the event's new FASHIONSUSTAIN conference.

FASHIONSUSTAIN at Ethical Fashion Show Berlin

The FASHIONSUSTAIN Berlin conference featured 20 speakers from 18 companies/ institutions and focused on "circularity" concepts looking at materials, processes, innovations, and industry applications.

Alexandra Cousteau

Representing the Good Impact Foundation, Alexandra Cousteau opened the conference with a hopeful introduction, sharing her insights into dealing with pollution caused by plastics and micro-plastics and reports on some initial transformations within the cotton industry.

Cousteau compiled her research by talking directly with fishermen and local farmers. As she attempted to motivate farmers to adjust their traditional towards more sustainable approaches, she says she discovered that they actually felt a sense relief in knowing that, for the first time, their actions were aligned with their belief system.

"It's a great time for the fashion industry to concentrate on exploring global textile cultures instead of exploiting this globe's human and ecological environments", Cousteau said. "The great thing that us all connects is the spirit of humanity."

Ellen Karp

Ellen Karp of Anerca provided results of a new survey about the current attitudes, changing behaviors, and outlooks of over 11,000 consumers in 10 countries as relates to textile sustainability.

Some key takeaways:

- 41% of participants asked to list "the top 5 issues that keep them up at night" chose "climate change" as their top concern (with 81% considering it "a real and serious problem");

- Trust and transparency play a significantly increasing role in consumer behavior with 42% of the people wanting to know about the values and principles of a brand;

- 40% of global participants "extremely or very concerned" about harmful substances in their clothing and home textiles. This figure rises to more than 70% in textile-producing countries such as China and India where people have closer proximity to the manufacturing process;

- While 90% of participants were aware of the existence of eco-friendly textiles, only 36% had actually bought them. Interestingly, these numbers were much higher for clothes designed for babies and small children.

Ecoalf

Javier Goyeneche's avid love of the oceans and marine life was evident in his presentation about his fantastic project, Ecoalf. It made me think of a quote from Sir David Attenborough: "Never has there been a more crucial time to reveal what’s going on beneath the surface of the seas".

Goyeneche explained that, due to laws which charge high fees to collect old nylon fishing nets, the sea has become a dumping ground for them — with 80% ‘lost’ by fishermen on their way back to harbor. Realising the high quality of the nylon used in manufacturing the nets, he connected scientists with fishermen and started a project called 'Upcycling The Oceans' in 2016. Slowly recovering the nets through local expeditions, the successful program has been replicated in Thailand and is now expanding to 60 ports. He reports that in Spain alone, the project has over 770 boats with 3,000 fishermen who are projected to reclaim 250 tonnes of nylon by the end of the year.

Apart from the recycled nylon, Ecoalf cooperates with specialists to recycle plastic bottles, wool, cotton, tires and coffee grounds to use as a base of a clothing range. Last year, Ecoalf has opened its first flagship store in Berlin.

Gustav Sandin Albertsson of Mistra Future Fashion

Based in Sweden, Mistra Future Fashion is a cross-disciplinary research program started in 2011. One of their projects is the development of Blend Re:Wind, a chemical recycling process of polyester/cotton fiber blends. While the cotton is turned into new high quality viscose filaments, the polyester is transformed into two pure new monomers.

Evelyn Mora, Helsinki Fashion Week

Evelyn Mora founded Helsinki Fashion Week to create a platform for fashion designers and labels in Finland — making sustainability a core element of the event's identity. Seeing how small independent designers often struggle to maintain the necessary stock to serve their markets, the organization is working to develop appropriate tools for sustainable mass production.

One such effort is called "The New Normal Project", created with the help of partners WWF Finland, Infinited Fiber Companies, and Hofstede Insights. The group is attempting to drive improvements at each stage of the production and supply cycle with the ultimate aim of achieving 100% sustainability in each area.

Ethicologist’s Disni Jayasuriya

"How can sustainable fashion brands achieve commercial success?" asked the Ethicologist’s Disni Jayasuriya. With 62% of clothing still being produced produced in sweatshops, she argues, consumer attitudes should shift away from boycotting specific brands and towards supporting ethical and sustainable brands. The reason: Most changes in consumer habits are only reactive short-term actions while only 15% change them in the long-term.

Jayasuriya also points out that "ethical brands" are often too small to fund appropriate communication and marketing strategies and the lack of visibility reduces consumer confidence and trust in these brands. To counteract this, she suggests knowledge exchanges (for example — friends trading website development skills for marketing insights). "True revolutions are not motivated by the super wealthy", she says — and also that she hopes idealistic people will share their stories and insights with one another.

Circularity at Greenshowroom

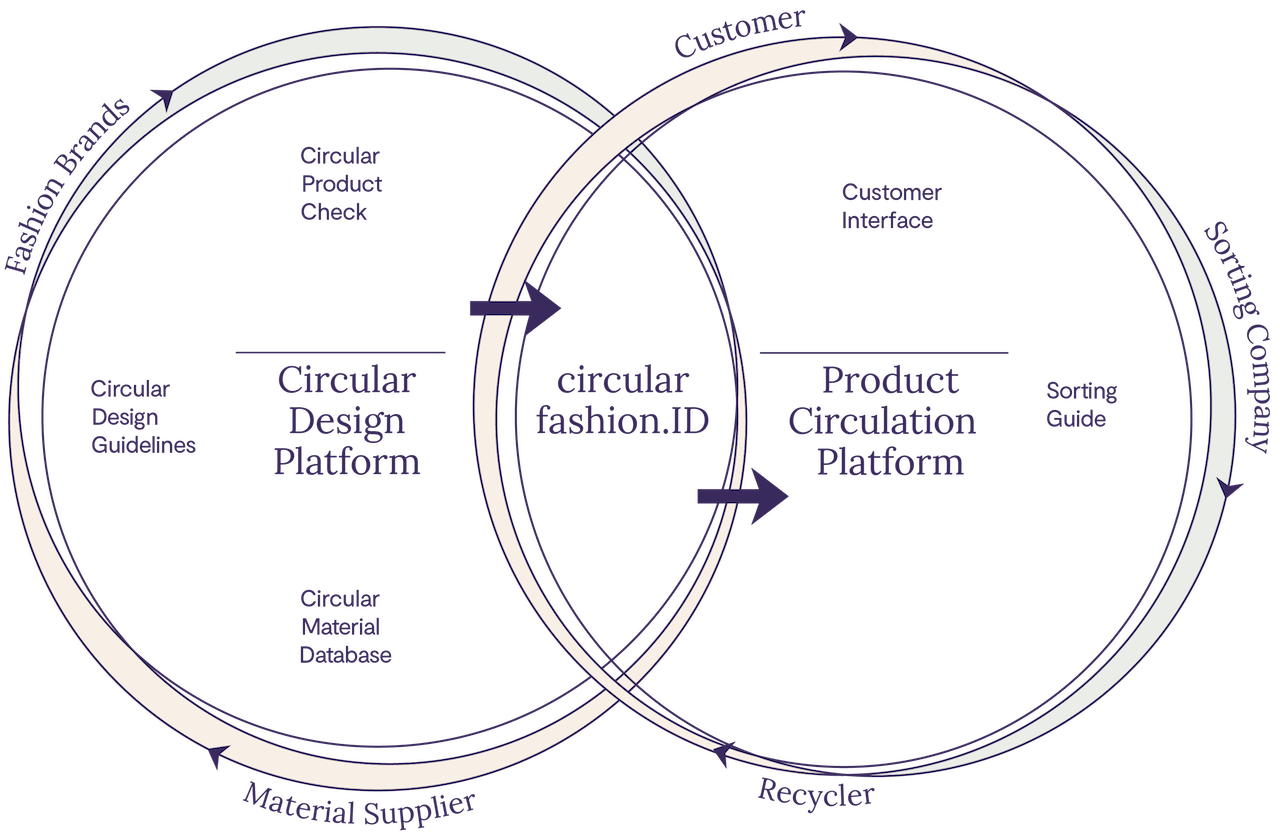

Continuing the theme of circular systems at Ethical Fashion Show Berlin, Ina Budde and Mario Malzacher presented their model, circular.fashion, as part of a GreenShowroom event which was happening simultaneously outside the FashionSustain conference.

According to the pair, 100 billion garments are produced each year — and 73% of those end up in a landfill. Budde and Malzacher have teamed up to find solutions to reduce that number.

At the moment, only 1% of garment-making materials are integrated into a "closed loop" recycling system. With a lack of good sorting systems, it's difficult to integrate with current machinery which can only recycle monomaterials.

Because of this, the identification of a garment’s material becomes crucial and so their Circular Design Platform attempts to address this need . It provides guidelines for production, as well as a materials database where designers are directly connected with suppliers. After a final product check ensures the final garment is composed of recyclable materials, designers are provided with a circularfashion.ID, which can then be attached to the garment.

This ID provides both the designer and the buyer with an interface to receive information on the full life of the garment — including its material composition, care instructions, and details about its production network. With the help of a sorting guide, customers receive information on how to send their garment to an appropriate textile recycler, who can then also use the ID to trace back the exact information about the material from its source.

FashionTech — Sustainability Highlights

The FashionTech event, now folded into the Ethical Fashion Show Berlin, focused on technical innovations and digitally-oriented developments related to the fashion and textile sector and, as you might expect, sustainability and circularity topics were also represented.

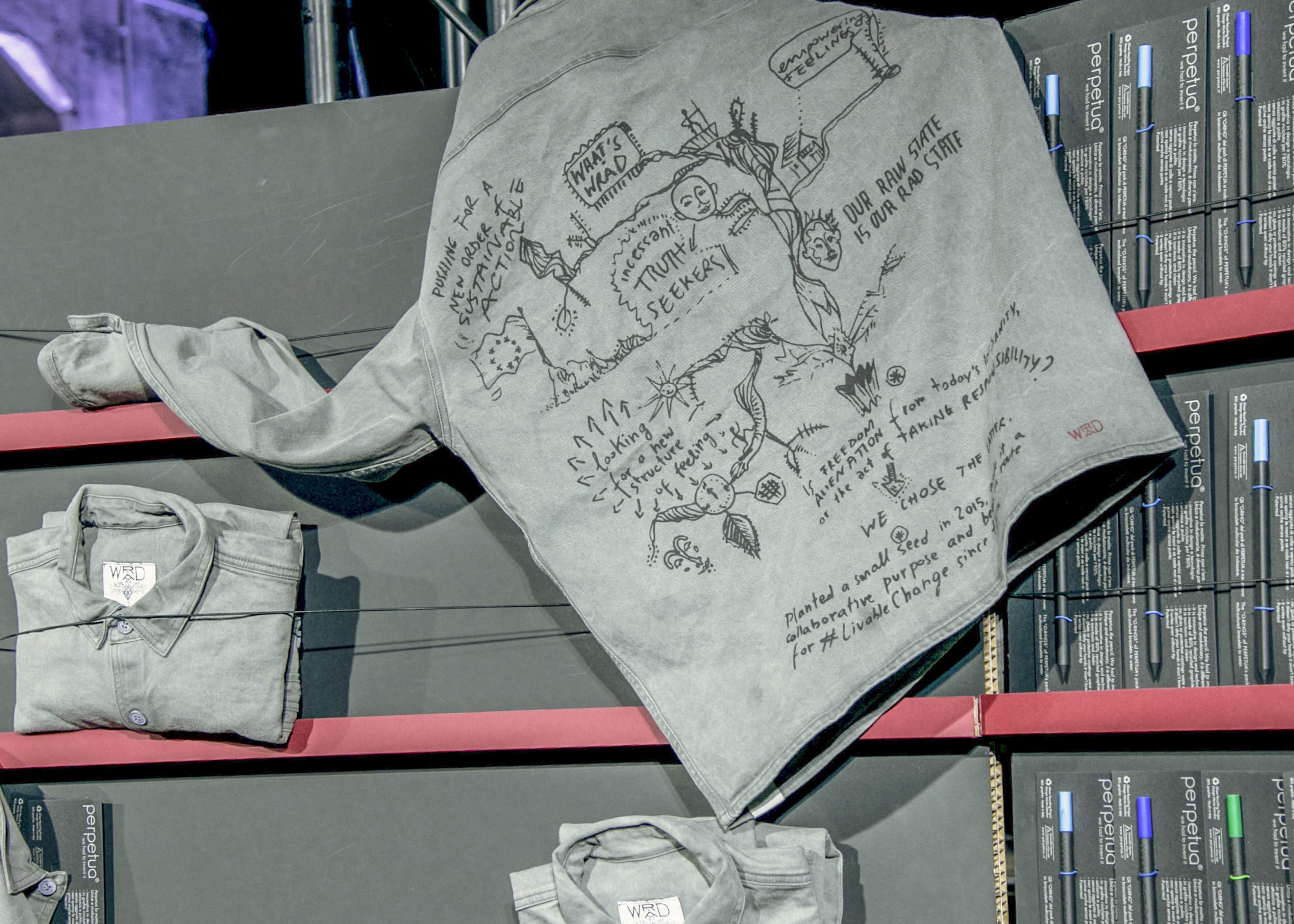

After six-and-a-half years of working with Abercrombie and Fitch, Matteo Ward decided he had to make a personal impact on the current state of fashion. His brand, WRÅD, uses recovered graphite powder from production waste that would normally end up in landfills. Growing the line from screen-printed tees, the company developed a new product range to showcase the latest iteration of this unique recycling technology.

Called G_pwdr, the process uses recycled graphite to dye fabrics and fibers. WRÅD also forged a partnership with Italdenim by using organic denim treated with KITOTEX, which is made from upgraded waste derived from food processing. The net effect? A 95% decrease in the water footprint during the dyeing stage and, by using Italdenim’s internal independent cogeneration plant, five standard manufacturing steps were eliminated and carbon emissions were reduced by 90%.