Susanne Stern, a Textile Designer who studied at Burg Giebichenstein University's textile workshop, remembers life as a young girl in East Germany: “Growing up in the GDR,” she said, “People had 2 pairs of 'good' clothes for special occasions — things you kept wearing for at least 10 years. Nowadays this wouldn’t happen, right?”

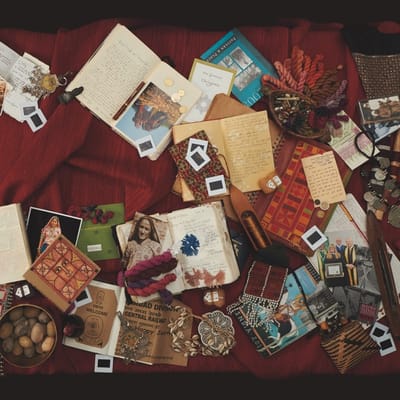

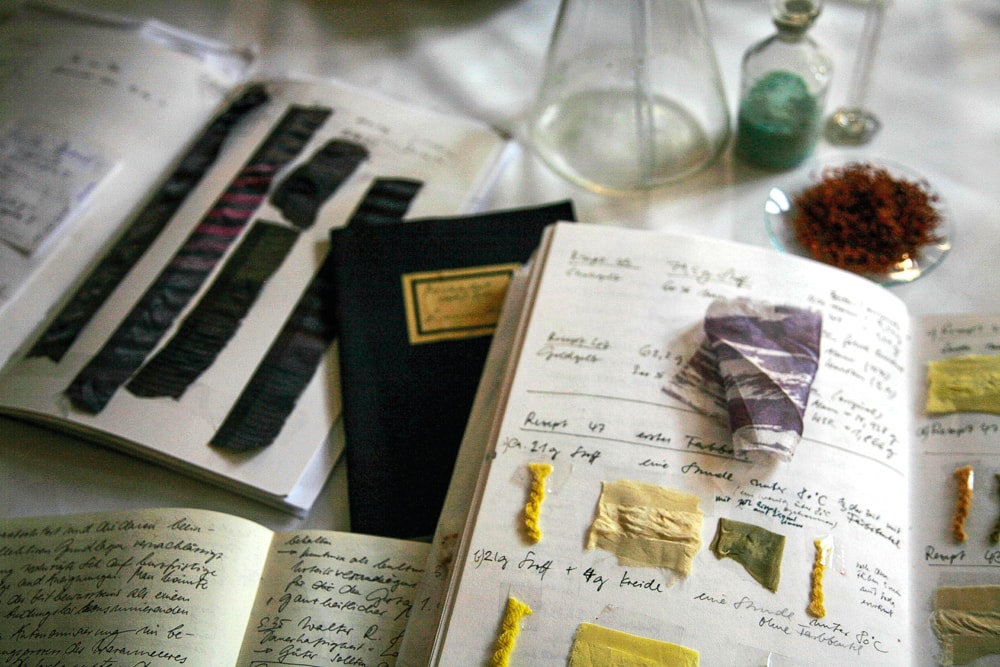

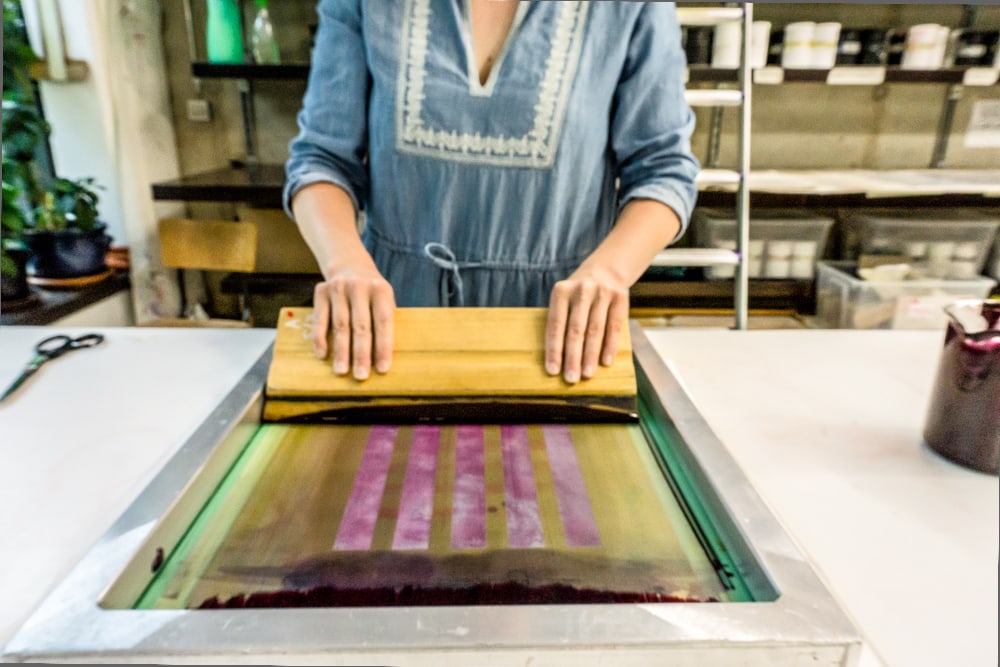

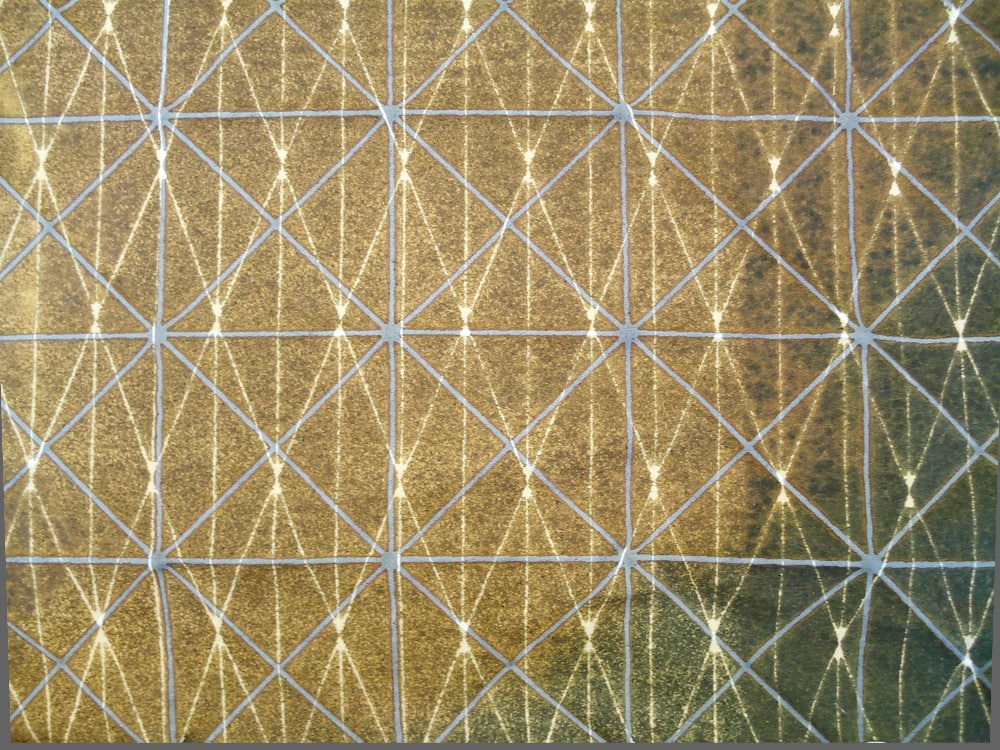

That experience — and her desire to find more local and eco-friendly ways of producing apparel — led to her thesis project: Hand-printed silk screens and corresponding natural dye printing pastes for use on silks and cotton. The specialized process she developed offered good fastness and a wide range of striking colors. Stern wondered: Could this technique become a commercially viable way to create long-lasting, beautiful garments?

Her new research project called “Organic Prints” aims to find the answer to that question. By bringing together a natural dye-extract producer, a textile print company, and an apparel maker at the beginning of the design process, her hope is that, together, they can develop an industrial process for bringing natural, non-toxic materials into the modern supply chain.

THE KINDCRAFT’s Laura Linsig recently interviewed Susanne to find out more. This interview was translated from German and has been condensed and edited for clarity.

THE KINDCRAFT

What inspired you to work with natural dyes?

Susanne Stern

While researching my Master's thesis, I began thinking about my future as a designer. I felt that it was important to create fabrics which were ecologically friendly and close-to-nature and, at the same time, also beautiful textiles in their own right. My dream was to create fabrics that could be composted but, at the same time, didn't obviously look it. In other words, they'd appeal to people primarily because of aesthetics — but if they looked deeper, they’d find a sustainable side as well.

It stood to reason to work with natural fibers and, since conventional dyes are made of refined mineral oil, it became obvious that natural dyes were the only choice to create fabric colors within my concept. My mom used to dye wool with natural dyes before and, as a teenager, I remember not being very thrilled with how it looked. When I started in 2010, the cliché was that natural dyes were rather unspectacular — a hobby for older women or history buffs — and so I wasn’t quite sure if it was the right way to go

During my first dyeing tests, though, I quickly learned that I could make a color chart which dispelled those clichés. I was surprised by the freshness and high aesthetic of colors that I could create and, what’s more, every single one of them fit with the others – no matter how they were combined.

That’s what gave me a new dream for my Master's thesis: To get natural dyes out of its quirky corner and to connect it with contemporary design.

THE KINDCRAFT

Why silk screening?

Susanne Stern

It wasn’t a conscious decision: The head of the university's textile workshop got the ball rolling with a hint. One day he walked into the dye workshop and said: “What do you think about printing with mordants?”

Once the first mordant prints had been made, the idea became bigger — to print with dyes. But how? Dyeing with natural dyes is fun, but the technique limits your scope for designs. You can obtain interesting effects by using shibori or reserve techniques but, even though batik and fadings have become more fashionable in recent years, my goal was to go to a level beyond the traditional results.

One terrific aspect of printing with natural dyes is the possibility of combining colors and patterns. Patterns work like an intercultural code: They tell you something about their historical origins and, therefore, about affinities, heritage and ages. Colors and symbols can be used by a designer — as well as by the consumer — to communicate moods and preferences. This is exactly what I wanted to make possible with my textile prints: The wearer decides what to express by their selection of clothing and fabric.

Another aspect appeared while working with those colors: Natural dyes appeal to humans in a special way. It is hard to explain why but, in my opinion, you can feel that those colors aren't made of refined mineral oil — but come from natural sources such as sun, wind and rain.

Every day, we have to find our bearings in a world that feels like it's diverging from nature. As soon as we see naturally grown and not human-made things–like on a hike through the forest, a walk on the beach, or a blossoming flower–we start to relax. For a moment, maybe we let go a little of our everyday stresses. While working with natural dyes, I often experience this feeling. The colors have a relaxing effect on me, which is noticeable.

My vision is to design fabrics that attract a large number of people and, at the same time, are honestly sustainable.

THE KINDCRAFT

How did this collaboration happen?

Susanne Stern

It’s a case of many puzzle pieces marvelously joining together! At the Ethical Fashion Show in Paris where I exhibited my master thesis, someone from NIG GmbH, a natural dye producer, introduced me to a staff member of Hess Natur, a well-known eco brand. As it happened, this person had already been working with natural dyes and was receptive to seeing what more could be done with them. Then my former professor helped me get in touch with KBC Fashion, one of the most important textile printing companies in Europe. KBC was established over 250 years ago and used to work with natural dyes in its earlier days before switching over to synthetic dyes when first introduced to the market many years ago.

At that point, the value chain for the research project was perfect: I had a producer of natural dyestuffs, an industrial textile manufacturer, and an apparel brand for sales and distribution.

THE KINDCRAFT

Expert knowledge about natural dyes is rare. How did you research this?

Susanne Stern

It required and almost uncountable series of tests… and a quite a lot of enthusiasm. When I talked to experts, many said “Nice idea, but it won’t work!”

Basically, the wheel had to be reinvented. In the beginning, there was almost no literature available which wasn't already been included in the thesis. I went through KBC's repository, reading books of pre-synthetic dye times and handwritten notes — but discovered these recipes weren’t compatible with modern industrial requirements. Another obstacle was that many old recipes contained tin and lead which were out of the question for use within modern, eco-friendly printing pastes. We ended up composing our own formula, step by step.

THE KINDCRAFT

What is the overall goal of “Organic Prints”?

Susanne Stern

We’re trying to bring some older techniques back into the industry. KBC itself used to work with natural dyes 250 years ago. "Natural and Sustainable" isn't a brand-new idea — but it’s red-hot today.

All of our partners want to do something for the greater good. We accept this challenge — even though we don't know if we'll be successful. What helps everyone take this risk is that the colors are so convincing! Often I hear people say: “I would have had never believed that natural dyes are so beautiful and had such radiance.”

As a textile designer, it’s also been my concern to design a fabric that isn’t toxic for the workers who make it, the people who are wearing it, nor for our environment which will absorb the discarded pieces. Some years ago, I watched a documentary about workers in Bangladesh who dyed fabrics, their bare arms and legs constantly submerged within swimming-pool sized dye vats. These toxic substances also pass the bodies of the consumers, into our sewage and, eventually, back into our food supply and our bodies.

THE KINDCRAFT

Any predictions for the future?

Susanne Stern

In my opinion, everything is possible — so long as companies and consumers are open to it.

We're all part of an enormous consumption routine — one which makes it harder to produce products made only of natural substances. I think it’s important to create products that draw the attention of a bigger crowd. People will have to–at least at first–spend a bit more money for long-lasting, eco-friendly goods. At the moment, though, the trend is going the other way: people are being conditioned to spend less money on more disposable clothes.

There are also technical challenges: the difficulty of producing a large amount of natural extracts and achieving color consistency which, just like different vintages of wine, can vary with changing amounts of sun and rain. As every textile designer working in the industry knows, that can be a real nightmare!

It may not be possible to fulfill every ethical and ecological aspiration straightaway. For example, some groups are using combinations of natural indigo and synthetics and–so long as it’s labeled as such–I think it’s still a step in a positive direction.

Our overall way of thinking must change if natural products hope to have a chance with mainstream consumers. If step-by-step, we can change this common mindset, I think we’ll open possibilities and spaces not only for old techniques like natural dyeing, but for many other new ideas as well.